TECHNICAL SUPPORT

CUNTACT US

Address:Power Research Center, No. 2588 Changyang Road, Shanghai

Address:Power Research Center, No. 2588 Changyang Road, Shanghai

Telephone:021-35303531

Telephone:021-35303531

Hotline:400-666-9179

Hotline:400-666-9179

Fax:021-35303532

Fax:021-35303532

Application of Copper Mesh Gasket in the Joint Surface of Steam Turbine Cylinder

This article introduces the application of copper mesh gasket on the joint surface of high pressure steam turbine cylinder and its process implementation. Practice has proved that the copper mesh gasket is an effective, simple and feasible method to eliminate the gap between the joint surface of the cylinder and control the leakage of the joint surface.

1. Analysis of the cause of steam leakage at the joint surface of the high-pressure cylinder

The high pressure cylinder of a steam turbine is an adiabatic work body that works under high temperature and high pressure conditions. In the vicinity of the regulating stage and the high-pressure shaft seal, the metal temperature in the cylinder flange is as high as 510°C. The root cause of steam leakage at the joint surface of the high-pressure cylinder is the deformation of the cylinder flange. There are two reasons for the deformation: one is that due to insufficient tempering during the manufacturing process, the residual content will gradually decrease with the extension of the operating time and the internal stress relaxation; the second is due to the thermal stress generated when the temperature changes during operation. To.

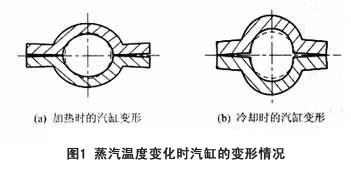

The upper and lower flanges of the high-pressure cylinder of the steam turbine, when the unit is started or the steam temperature rises, the metal ## on the inner surface of the cylinder is heated and expanded, but it is restrained by the unheated metal outside to produce stress. Under the action of thermal stress in the horizontal direction, the upper and lower walls of the cylinder deform greatly and the cross-sectional shape of the cylinder becomes flat ellipse. The flange has an external opening, the flange fastening bolts are stretched, and the inner sealing surface of the flange is greatly squeezed. When the metal of each part of the cylinder is heated evenly, the ellipse returns to a circle, and the outer opening disappears. However, due to the plastic elongation and tightening force of the bolt, the compressed part of the flange inner sealing surface cannot be restored, resulting in a gap. Leakage occurred at the flange joint. When the steam temperature drops rapidly, the inner surface of the cylinder cools and shrinks sharply. Contrary to the above-mentioned situation, the flange has an internal opening and the inner sealing surface of the flange leaks. Figure 1 shows the deformation of the cylinder when the steam temperature changes.

2. Disadvantages of traditional treatment methods

During overhaul, methods such as grinding, spraying, and coating are often used to eliminate the gap between the cylinder joints, but they all have the following shortcomings: heavy workload; unsatisfactory performance of coating, plating and cylinder block; weak elastic compensation ability; easy to rebuild A gap appears. It is easy to leak again during the operation of the unit after overhaul. In the case that the traditional treatment method cannot meet the sealing requirements of the ## cylinder joint surface, it is a simple and feasible method to use copper mesh gasket combined with cylinder sealant to eliminate the leakage of the joint surface of the high pressure cylinder.

3. The application effect of copper mesh gasket

Copper is a soft metal whose linear expansion coefficient is much larger than that of alloy steel. The ## advantage of the copper mesh gasket is that it has good flexibility. Under high temperature and heating conditions, it can compensate itself with the size of the gap generated by the deformation of the cylinder, and it has strong adhesion.

3-1. Copper mesh annealing treatment According to the size of the cylinder joint surface gap, after selecting the copper wire mesh (cloth) specification, put it in the heating furnace, heat it to 650-700℃, keep the temperature for 30 minutes, and then take it out for water cooling. After annealing, the hardness of the copper mesh decreases and becomes soft.

3-2. After the joint surface of the high-pressure cylinder is cleaned up by the gasket template, the upper cylinder is buckled, the gap is checked with a feeler gauge, and the gap value is marked on the inner and outer sides of the lower cylinder wall with a color pen, and then the cylinder is pressed down with a green cardboard to join The inner and outer sealing surface profile lines are sampled separately, divided into several sections according to the difference of the gap value, and the gaps of each section are correspondingly recorded on the green cardboard.

3-3. Production of copper mesh gaskets According to the prepared paper shell template, cut the copper mesh, place it on a clean and smooth steel plate platform, squeeze it with a round head hammer, check with a micrometer caliper, and squeeze it to The corresponding thickness on the cardboard is sufficient (generally, the thickness of the copper mesh gasket is required to be 0.05 mm smaller than the gap value, as the bolt tightening amount, if the gap is large, a two-layer copper mesh can be considered).

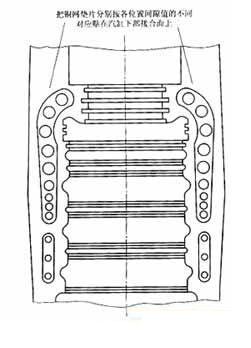

3-4. The copper mesh gasket is installed on the joint surface of the cylinder with the high pressure cylinder buckle. After applying the cylinder sealant, the copper mesh gasket is attached to the lower joint surface of the cylinder according to the gap value, and be careful not to misplace. Or fold them together, and then tighten the bolts. Figure 2 is a schematic diagram of installing copper mesh gaskets.